Reuse Plastic Waste

Veltkamp ISO 14001 - Environmental management

Veltkamp is ISO 14001 certified. This is the international standard for an environmental management system based on an appropriate environmental policy.

Veltkamp uses technical plastics for the production of plastic products.

In addition, for the most part, use is made of recycled plastic waste or recyclate.

Why Recyclate?

Recyclate is made from plastic household, industrial and ocean waste. For example old bottle caps, household waste bins, diaper plastic, car bumpers, etc.

Availability depends on the quality of the collection of this waste in a country.

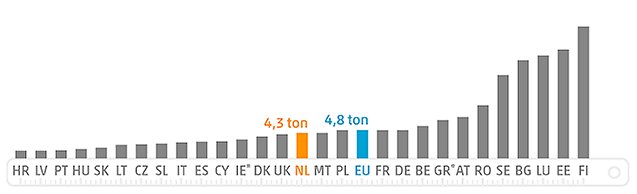

The Western European countries, including the Netherlands, mainly use recycling and composting of this waste. In addition, some of it is burned for district heating or the generation of electricity.

In southern and eastern Europe, on the other hand, most of the waste is landfilled. Only a very limited part is incinerated or processed differently.

Availabilty

It is of course very important that there is also a constant supply of recyclate. In practice, this is not always the case. Shiploads of recyclate are regularly sold on their way to a European port and shipped to countries such as China.

The availability of suitable recyclate in a constant flow is therefore limited.

Price

The price depends in particular on availability. In addition, also of the increasing demand on the world market for environmentally friendly production. As a result, recyclate is sometimes even more expensive than new material.

Contrary to all advertisements, it is therefore not always easy to produce more environmentally friendly with recyclate. It even happens that products are propagated as environmentally friendly, but that a mix of new material and recycled material is used due to lack of availability and pricing.

What about Bioplastics?

Bioplastics are artificial polymers made from PLA (Polylactic acid). PLA is produced from starch using a chemical process. However, this does not mean that the plastic itself is biological and therefore does not mean that the plastic is biodegradable. These bioplastics are compostable under certain industrial conditions. However, this requires a high energy consumption to be able to break down the molecular chains.

The percentage of added filler can vary considerably and this often has an adverse effect on the mechanical properties of the plastic.

Some fillers should also not be left outside or in a moist environment for too long. For example, with wood, the weight increases again disproportionately.

Furthermore, developments are underway in which fillings are added to both synthetic and bio plastics. A disadvantage here is the CO2 emission due to the transport movements of the filler and the plastics to the mixing location. There the plastics are remelted and then granulated. Not only does this cost a lot of energy, but the substances can no longer be decomposed.

At the end of life cycle, these plastics can only burn completely. This while a pure plastic can be recycled again.

The Bioplastics are intended to replace disposable packaging. But the material is therefore not biodegradable in nature, but must be processed in special composting plants.

Plastics remain plastics and do not belong in nature. Plastics that eventually disintegrate are micro plastics that can no longer be obtained from nature with current techniques.

Bioplastics are also considerably more expensive. As a result, the final product costs are currently too expensive for many consumers.

CO2 footprint Biobased Plastics

The European Commission has determined that bioplastics are important in limiting climate change, partly because of the lower CO2 footprint.

A larger share of biobased products could be supplementary to recyclates, and thus also contribute to the reduction of greenhouse gas emissions.

Bioplastics have a CO2 footprint that can be 50 to 80% less than that of virgin plastics.

With recyclate, the footprint is virtually nil.

Plastic Pact Netherlands

In 2019, the Plastic Pact was agreed between the Dutch government and the business community to make the switch to plastics from sustainably produced biobased raw materials. Not to solve the plastic soup, but to reduce dependence on fossil raw materials and thus contribute to climate goals.

An important problem for waste processors, however, is that bioplastics make the recycling of ordinary plastics more difficult. In practice, the consumer supplies a mix of all types of plastics, both standard plastics and bioplastics. This disrupts the composting process.

Many composting companies therefore remove all types of plastic as much as possible, including those that would degrade.

Conclusions