About Strapping and Lashing

The difference between Strapping and Lashing:

These two groups can be divided into 6 types:

|

|

|

PP - Strapping Extruded Polypropylene |

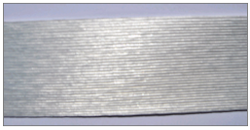

PET - Strapping Extruded Polyester |

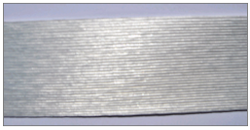

Hotmelt - Strapping Glued Polyester |

|

|

|

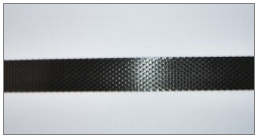

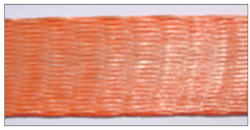

Composite - Strapping/Lashing Co-extruded Polyester |

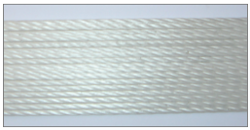

Polyester Lashing Woven Polyester |

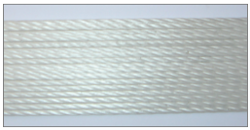

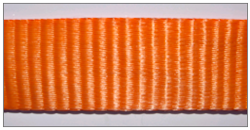

Polypropylene Lashing Woven Polypropylene |

Application Areas

Strapping/Lashing type |

Applications |

Closures |

|

PP |

|

|

|

PET |

|

|

Hotmelt |

|

|

Composite |

|

|

Woven Polyester |

|

|

Woven Polypropylene |

|

|

Safety Standards |

Applicable in Europa |

Applicable in USA/Canada |

Strapping = secure on pallets: |

|

|

Lashing = cargo securing: |

|

|

The quality of band is among others determined by the tensile strength of the strapping/lashing:

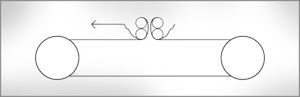

| According to the EN 12195 and ASTM 3950-D the Tensile Strength has to be determined with a series linear tensile testing of the strapping/lashing. |

|

This continued with a series of tensile tests of the band combined with a buckle or frame. The result must be at least 55% of the linear tensile tests with only the strapping/lashing. |

|

In order to be able to come with a higher value customers is often the System Strength specified. This System Strength is only used as a selling point and is in fact the double value of the Linear Tensile Strength because the band is double. The System Strength is not applicable in testing protocols. |

|

Also at the System Strength is often specified a value for the band and then the band with a buckle or frame in system. |

|

About Strapping and Lashing

The difference between Strapping and Lashing:

These two groups can be divided into 6 types:

|

|

|

| PP (extruded polypropylene) - Strapping | PET (extruded polyester) - Strapping | Hotmelt (glued polyester) - Strapping |

|

|

|

| Composite (co-extruded polyester) - Strapping/Lashing | Woven Polyester - Lashing | Woven Polypropylene - Lashing |

Application Areas

Strapping/Lashing type |

Applications |

Closures |

|

PP |

|

|

|

PET |

|

|

Hotmelt |

|

|

Composite |

|

|

Woven Polyester |

|

|

Woven Polypropylene |

|

|

Safety Standards |

Applicable in Europa |

Applicable in USA/Canada |

Strapping: |

|

|

Lashing: |

|

|

The quality of band is among others determined by the tensile strength of the strapping/lashing:

In order to be able to come with a higher value customers is often the System Strength specified. This System Strength is only used as a selling point and is in fact the double value of the Linear Tensile Strength because the band is double.

The System Strength is not applicable in testing protocols.

Also at the System Strength is often specified a value for the band and then the band with a buckle or frame in system.