|

|

Type of Products

|

|

|

|

|

|

|

| Roundslings professional |

Roundslings with Jacket |

Endless Slings SF 7 :1 - 1 or 2 layers |

Endless Slings SF 5 :1 - one way |

Lifting Slings - loops 2 or 4 layers |

Coil Slings heavy duty |

Sleeves for Protection |

Type of Covers

|

|

|

|

|

|

| STE Single Polyester |

STD 2-Layers Polyester |

Pro 2-way woven Techlon |

Pro-C Polyester and Cordura |

Pro-Ultra 2-way woven Dyneema |

Protection Covers 4-way Dyneema |

Ratios in wear resistance =

Techlon : PES = 2 : 1 / Cordura : PES = 5 : 1 / Dyneema : PES = 50 : 1

Round Slings

| Type: | WLL-standard: | Expandable to: | Material core / cover: | Article Numbers: |

| STE | 1 - 10 tons | - | polyester / 1 layer polyester | 30200001 – 30200080 |

| STD | 1 - 10 tons | - | polyester / 2 layers polyester | 30202001 – 30202080 |

| Pro | 1 - 120 tons | 250 | polyester / 2 together woven layers Techlon | 30210001 – 30200192 |

| Pro-C | 10 - 120 tons | 250 | polyester / 1 layer polyester + 1 layer Cordura | 30220001 – 30220144 |

| Pro-X | 10 - 120 tons | 250 | Dyneema / 1 layer polyester + 1 layer Cordura | 30230001 – 30230144 |

| Pro-Ultra | 2 - 180 tons | on request | Dyneema / 2 together woven layers Dyneema | 30240001 – 30240190 |

Lifting Slings with Loops

| Type: | WLL-standard: | Material core / cover: | Article Numbers: | |

| SLS | 1 - 12 tons | 2 layers polyester | 30050001 – 30050500 | |

| Prolift-S | 2 - 40 tons | 4 layers polyester | 30100001 – 30100144 | |

| Prolift-TT | 1 - 10 tons | 2 layers polyester | 30072001 – 30072064 | |

| Prolift-TT | 10 - 25 tons | 4 layers polyester | 30074001 – 30074044 | |

| Prolift-TD | 1 - 10 tons | 2 layers polyester | 30082001 – 30082044 | |

| Prolift-TD | 10 - 25 tons | 4 layers polyester | 30084001 – 30084044 |

Regulations textile lifting equipment:

|

|

WLL

The Work Load or maximum load (Working Load Limit - WLL) is the maximum permissible payload that may be hoisted during law lifting work.

This is significantly lower than the theoretical tensile strength (Minimum Breaking Load - MBL), depending on the lifting equipment and the work.

The usage factor or safety factor SF at lifting with steel cables is 5, whereas slings on 7.

In the past, instead of WLL uses SWL or Safe Working Load. Today is also still used. This must be a value that has been adapted to the specific situation, if there is not,

for example right is hoisted.

| Working Load Limit = | minimum breaking strength |

| safety factor - 7 |

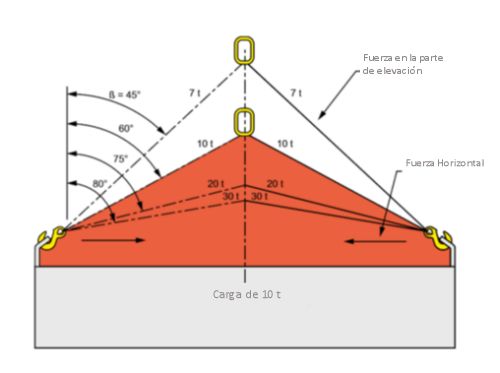

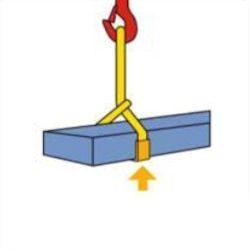

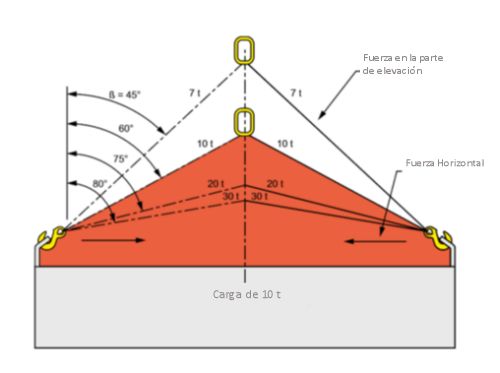

Larger inclination angle (outside corner) ß = higher load (force) in each part.

Note: The load must withstand the horizontal forces! |

|

Lifting Chart = Load rating with inclination angle (outside corner) ß

| ß = 0 - 7º | ß = 0 - 7º | ß = 0 - 7º | ß = 7 - 45º | ß = 45 - 60º | ß = 7 - 45º | ß = 45 - 60º | ß = 7 - 45º | ß = 45 - 60º | ß = 7 - 45º | ß = 45 - 60º |

|

|

|

|

|

|

|

|

|

|

|

| WLL = 100% | WLL x 0,8 | WLL x 2 | WLL x 1,4 | WLL = 100% | WLL x 0,7 | WLL x 0,5 | WLL x 1,4 | WLL = 100% | WLL x 1,12 | WLL x 0,8 |

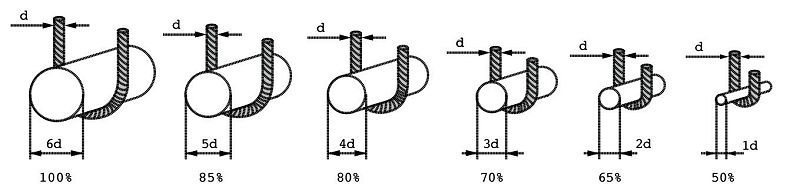

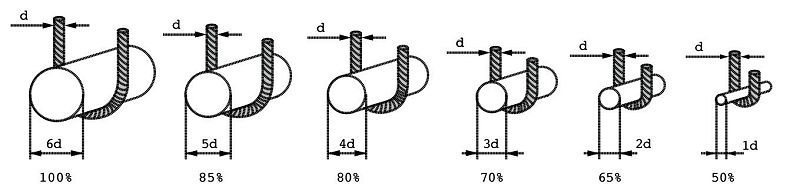

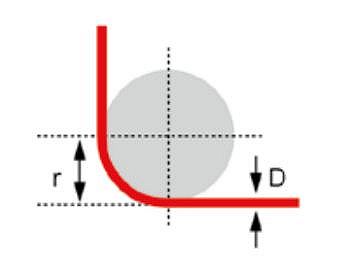

Bending Radius D/d

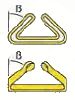

Keep in hoisting in pants form (also known as basket) always consider the ratio diameter / bending radius of the hoisting tool to select suitable hoist (D/d = 6 : 1 = 100% WLL).

Periodic inspection for damage = at least 1 x per year.

Avoid wet and ice formation.

Sharp Edges A sharp edge occurs when the radius of the edge is smaller than the diameter of around sling or lifting belt. Use Dyneema and/or protective covers. |

|

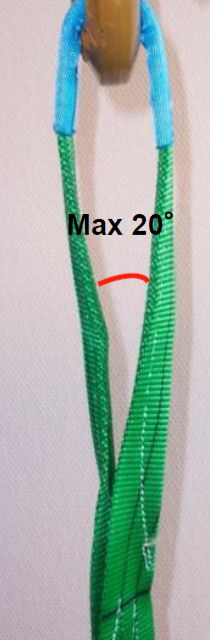

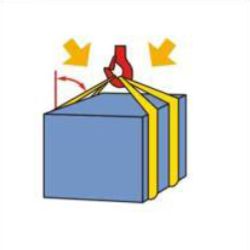

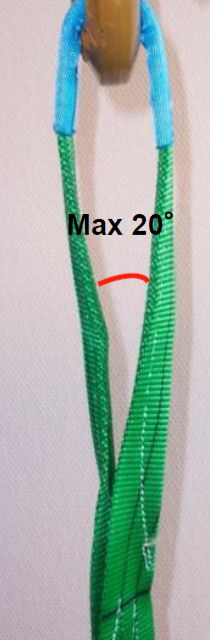

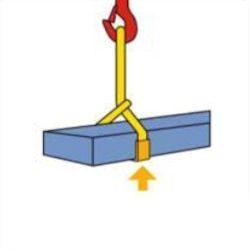

Right type crane hook: 1. The minimum length of the loop must be at least 3.5 x the thickness of the crane 2. The inside corner of the loops on the hook, must not be greater than 20 degrees |

|

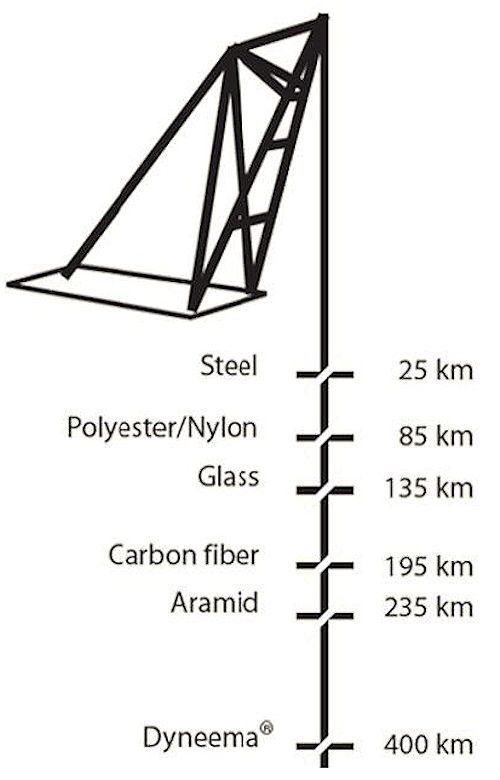

Dyneema®

Apply when:

|

|

Rejection criteria:

|

|

Recognition cause breakage

|

|

| Breakage due to overload | Breakage due to incision |

Points of attention

|

|

|

|

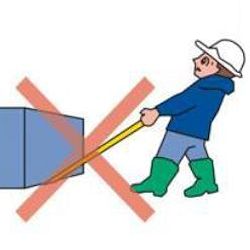

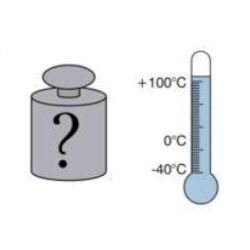

| Avoid overload of the WLL and Temperature |

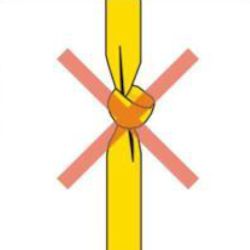

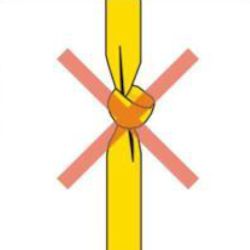

Avoid knots and twisting |

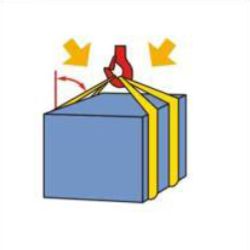

Use corner protection at sharp edges and corners |

Inspect the equipment for use for damage |

|

|

|

|

| Avoid excessive lifting angle |

Avoid contact with chemicals |

Avoid use of damaged equipment |

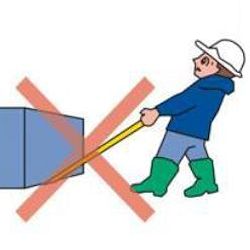

Prevent the load rests on the slings |

Veltkamp focuses with lifting equipment under the hook especially on the professional market.

On the website are the standard dimensions and types.

Different types, size and project specific products are available on request.

All delivered products comply with the EN 1492-1, EN 1492-2 with safety factor SF 7:1.

Exception are the One Way Endless Slings (type ESO):

All products also conform to Machinery Directive 2006/42/EC and are therefore provided with a CE mark.

Type of Products

Type of Covers

Ratios in wear resistance =

Techlon : PES = 2 : 1 /

Cordura : PES = 5 : 1 /

Dyneema : PES = 50 : 1

Round Slings

| Type: | WLL-standard: | Expandable to: | Material core / cover: | Article Numbers: |

| STE | 1 - 10 tons | - | polyester / 1 layer polyester | 30200001 – 30200080 |

| STD | 1 - 10 tons | - | polyester / 2 layers polyester | 30202001 – 30202080 |

| Pro | 1 - 120 tons | 250 | polyester / 2 together woven layers Techlon | 30210001 – 30200192 |

| Pro-C | 10 - 120 tons | 250 | polyester / 1 layer polyester + 1 layer Cordura | 30220001 – 30220144 |

| Pro-X | 10 - 120 tons | 250 | Dyneema / 1 layer polyester + 1 layer Cordura | 30230001 – 30230144 |

| Pro-Ultra | 2 - 180 tons | on request | Dyneema / 2 together woven layers Dyneema | 30240001 – 30240190 |

Lifting Slings with Loops

| Type: | WLL-standard: | Material core / cover: | Article Numbers: | |

| SLS | 1 - 12 tons | 2 layers polyester | 30050001 – 30050500 | |

| Prolift-S | 2 - 40 tons | 4 layers polyester | 30100001 – 30100144 | |

| Prolift-TT | 1 - 10 tons | 2 layers polyester | 30072001 – 30072064 | |

| Prolift-TT | 10 - 25 ton | 4 layers polyester | 30074001 – 30074044 | |

| Prolift-TD | 1 - 10 tons | 2 layers polyester | 30082001 – 30082044 | |

| Prolift-TD | 10 - 25 tons | 4 layers polyester | 30084001 – 30084044 |

Regulations textile lifting equipment:

WLL

The Work Load or maximum load (Working Load Limit - WLL) is the maximum permissible payload that may be hoisted during law lifting work.

This is significantly lower than the theoretical tensile strength (Minimum Breaking Load - MBL), depending on the lifting equipment and the work.

The usage factor or safety factor SF at lifting with steel cables is 5, whereas slings on 7.

In the past, instead of WLL uses SWL or Safe Working Load. Today is also still used. This must be a value that has been adapted to the specific situation, if there is not,

for example right is hoisted.

| Working Load Limit = | minimum breaking strength |

| safety factor - 7 |

Inclination Angle (outside corner) ß

The inclination angle (outside corner) is of paramount importance in the use of lifting attachments.

Larger inclination angle (outside corner) ß = higher load (force) in each part.

Inclination angles (outside corners) greater than 60 ° are forbidden!

Note: The load must withstand the horizontal forces!

Lifting Chart = Load rating with inclination angle (outside corner) ß

| ß = 0 - 7º | ß = 0 - 7º | ß = 0 - 7º | ß = 7 - 45º | ß = 45 - 60º | ß = 7 - 45º | ß = 45 - 60º | ß = 7 - 45º | ß = 45 - 60º | ß = 7 - 45º | ß = 45 - 60º |

|

|

|

|

|

|

|

|

|

|

|

| WLL = 100% | WLL x 0,8 | WLL x 2 | WLL x 1,4 | WLL = 100% | WLL x 0,7 | WLL x 0,5 | WLL x 1,4 | WLL = 100% | WLL x 1,12 | WLL x 0,8 |

Bending Radius D/d

Keep in hoisting in pants form (also known as basket) always consider the ratio diameter / bending radius of the hoisting tool to select suitable hoist (D/d = 6 : 1 = 100% WLL).

Sharp Edges

A sharp edge occurs when the radius of the edge is smaller than the diameter of around sling or lifting belt.

Use Dyneema and/or protective covers.

Periodic inspection for damage = at least 1 x per year.

Avoid wet and ice formation.

Right type crane hook:

Dyneema®

Apply when:

Product properties:

Rejection criteria:

Recognition cause breakage

Breakage due to overload

Breakage due to overload

Breakage due to incision

Breakage due to incision

Warnings

|

|

|

|

| Avoid overload of the WLL and Temperature |

Avoid knots and twisting |

Use corner protection at sharp edges and corners |

Inspect the equipment for use for damage |

|

|

|

|

| Avoid excessive lifting angle |

Avoid contact with chemicals |

Avoid use of damaged equipment |

Prevent the load rests on the slings |